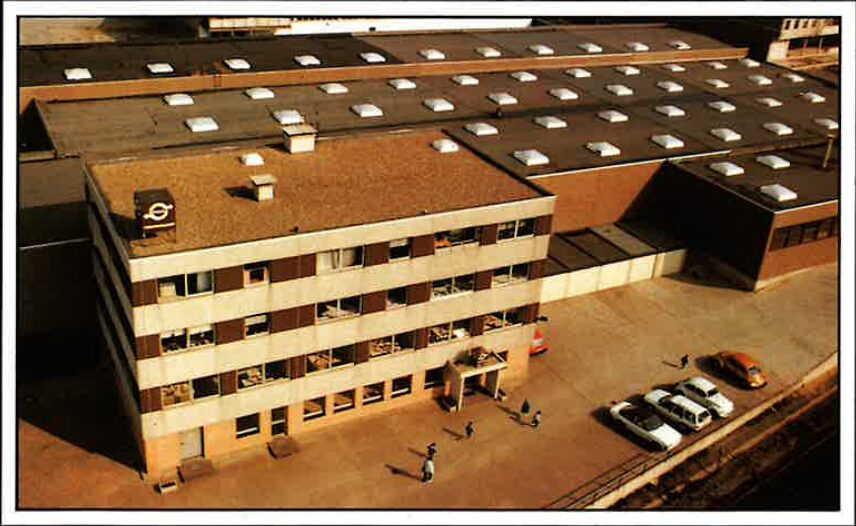

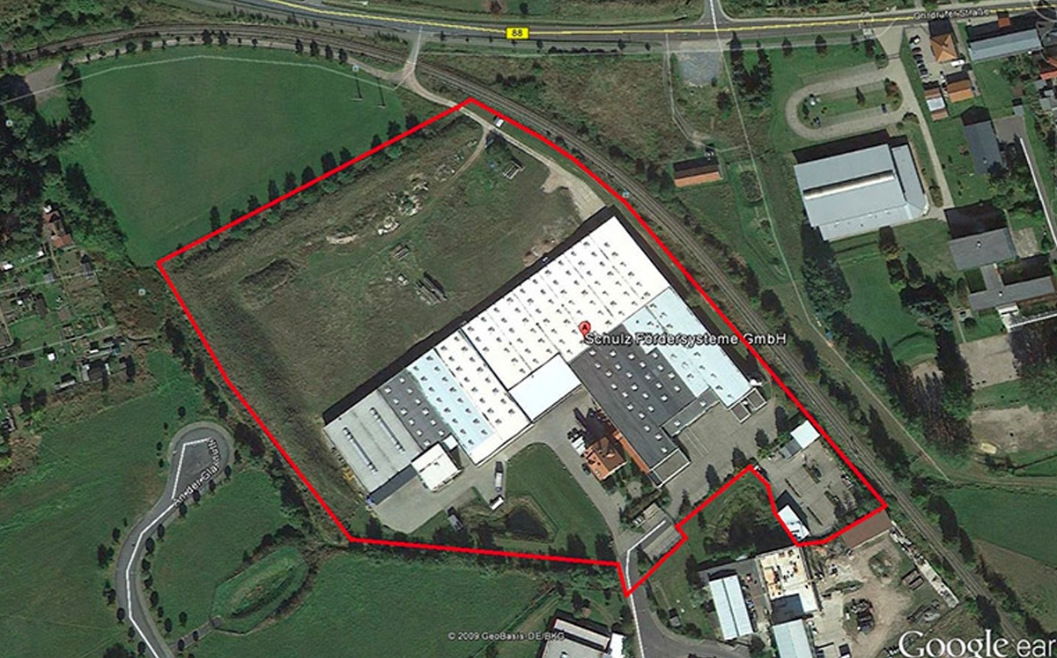

Schulz Conveyor Systems LLC, based in Gräfenroda, was founded in 1991 by Mr Peter Schulz. Immediately after its foundation, the company began to invest in the latest technologies. Favoured by laser cutting technology, which had its technical breakthrough at the beginning of the 1990s, the clientele grew rapidly and also the company. Within a few years, a state-of-the-art sheet metal production facility was built on the former site of an old glass factory. Laser technology was followed by technologies such as bending and welding.

In 1997, Schulz Conveyor Systems took over part of Gothaer Vehicle Production Plant. This opened up a new line of business for the company – the automotive industry.

Today, Schulz Fördersysteme GmbH is a solid medium-sized company that adapts to the increasing and fluctuating market situations and requirements through flexible, broad-based manufacturing and processes. It specialises in the production of welding and assembly components, as well as laser and edging parts.

In order to continue the company’s success in the future in the usual manner, the following entrepreneurial goals are being pursued:

- Expansion and consolidation of market position

- Manufacturing at the highest technical level

- Delivery of the best quality

- Automation of Manufacturing

- Increasing technical expertise to support customers with design issues and cost reduction

- Increasing the vertical range of manufacture